Cummins KTA19 / CIP

KTA19

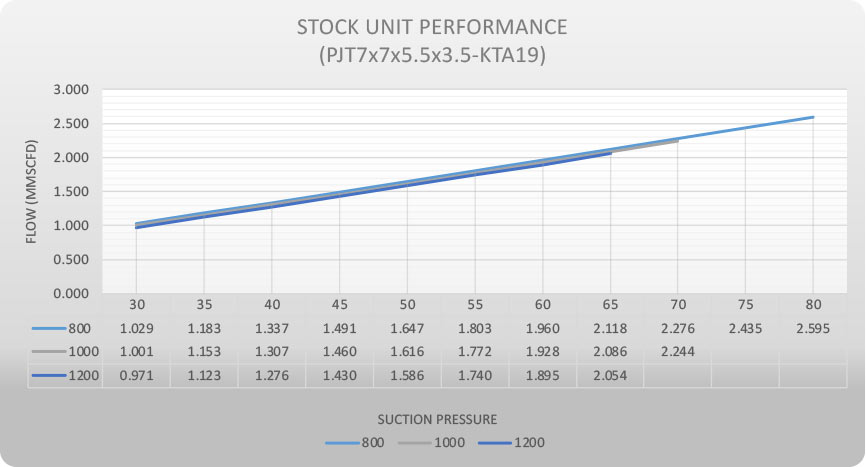

- 420 HP

- 2.0 MMSCFD @1200psig

- 2.5 MMSCFD @800psig

- 0.5 NOx (g/Hp-Hr)

- 2.0 CO (g/Hp-Hr

- 0.7 NMHC (g/Hp-Hr

Above stock unit performance can be optimized around other conditions. Contact NGSG for your specific needs.

NGSG SMART System Highlights:

- Reduce shutdowns by as much as 25% over industry standard compressors*

- 100% turn down of flow - 24/7/365

- Elimination of pressure, horsepower, and rod load related shutdowns

- Rock-solid pressure control over the widest range of process needs & upsets

- Robust freeze avoidance for uninterrupted operation in cold weather

- Run through fluctuating BTU fuel gas upsets rather than shutting down

- Maximum power and flow optimized over the entire range of process conditions – done automatically

- When N+1 units are installed, compressor flow reliability approaches 100% as the multiple machines automatically increase flow to fill gap when unit goes down

- Dewpoint control – Temperature process control to within 2-4°F of setpoint

- Telemetry via cellular or satellite of package data (includes ALL engine panel information too):

- Remote setpoint allowable

- Monthly sorting and tally of alarms/shutdowns for continuous improvement

- Both, customer connection at panel & web-based access to real time and historical data

Environmental Engineered Aspects:

- Pneumatic end devices made electric (standard)*

- Electric start*

- Crank case and packing vent capture (option)*

- Lower engine emissions

- Electric drive (option)*

Package Features:

- All vessels meet ASME Section VIII standards with 1/8” corrosion allowance

- All vessels meet API 11P Class C standard

- All piping systems meet ASME B31.3 standard

- API 618 Design Approach 2 pulsation and mechanical analysis performed for smooth operations

- Standard design to maximize parts availability and minimize downtime

- Suction control and recycle valves – Murphy C5 controller. Recycle valve is mounted on skid

- DP pressure and temperature monitoring across exhaust catalyst

- Rigid four beam skid with 1.5 times capacity environmental containment designed for packed earthen pad

- NGSG custom fuel gas scrubber for maximum engine protection

- Electrical rating service of Class 1, Group D, Division II areas*

- NGSG custom designed, Murphy C5 controlled inner and outer louvers, separate for each process gas section – These louver sections do not require frequent adjustments and repairs like industry standard louvers

- No hot gas bypass required*

- NGSG’s custom flooded skirt heat tracing to avoid package liquid line freeze ups

- 500 psig MAWP blow case on separate skid (Option)

- Critical Grade engine exhaust silencer

- Murphy C5 Controller - fully integrated with engine messages and alarms

Driver: Cummins KTA19GCE 420hp@1800rpm w/ EICS Controls

- Murphy EICS Emissions Control System designed to achieve 0.5g/bhp-hr NOx

- Electric start system with on board battery charger

- EICS Engine Management

Compressor: CiP PJT/4

- 600 BHP 4-Throw Frame

- 750-1800 RPM

- 3” Stroke

- 20,000 lbf Total Rod Load (11,000 lbf Compression, 10,000 lbf Tension)

- VVCP’s on all cylinders

| Compression Stage | Cylinder | MAWP |

|---|---|---|

| 1st Stage | 7” / 7” | 300 / 300 |

| 2nd Stage | 5.5” | 1270 |

| 3rd Stage | 3.5” | 1725 |

Cooler: 60” ETR OFE Forced Draft Vertical Discharge

Minimum design parameters:

- 3,000’ elevation

- 110°F ambient with 5% excess cooler duty

- Compressor PTO driven cooler fan

- All tubes SA 214 Carbon Steel with Aluminum fins

- Individual auto louvers inside and outside each gas section

- ASME Code Stamp per ASME Section VIII, Div 1 with Nat’l Board Registered

*Contact NGSG for details

** Size may change slightly due to minor improvements. Confirm size with NGSG drawings