Caterpillar G3306 TAA / CIP

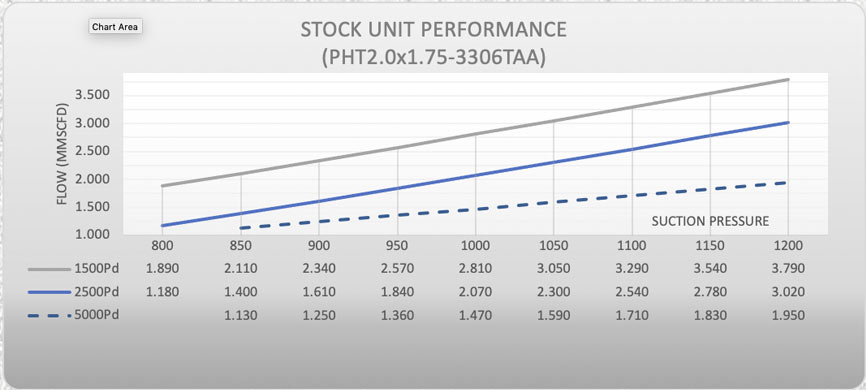

3306TAA

- 211 HP

- 0.9 MMSCFD @1200psig

- 1.2 MMSCFD @800psig

- 0.5 NOx (g/Hp-Hr)

- 2.0 CO (g/Hp-Hr

- 0.7 NMHC (g/Hp-Hr

Package Features:

- All vessels are designed and built to meet ASME Section VIII with 1/8” corrosion allowance

- Suction vessel designed to API 11P Class C

- Electrical rating service of Class 1, Group D, Division II areas*

- NGSG custom two stage coalescing fuel gas scrubber for maximum engine protection

- All piping meets or exceeds ASME B31.3

- API 618 Design Approach 2 pulsation and mechanical analysis performed for smooth operations

- Rigid skid with 1.5 times capacity environmental containment designed for packed earthen pad.

- NGSG’s custom flooded skirt heat tracing to avoid package liquid line freeze ups

- Critical Grade Silencer

- On skid recycle valve

Driver: Caterpillar G3306TAA 220hp @1800 rpm w/ EICS Controls

- Murphy EICS Emissions Control System designed to achieve 0.5g/bhp-hr NOx

- Electric start system

- EICS Engine Management

- Electric End Devices (standard)

Compressor: CiP PHT/2

- 250 BHP 2-Throw Frame

- 50-1800 RPM

- 3” Stroke

- 20,000 lbf Total Rod Load (11,500 lbf Compression, 10,500 lbf Tension)

| Compression Stage | Cylinder | MAWP |

|---|---|---|

| 1st Stage | 2.0625” | 3975 |

| 2nd Stage | 1.7500” | 5500 |

Cooler: Kim-Kool Air-Coolers or equivalent

Minimum design parameters:

- 3,000’ elevation

- 110 oF ambient

- All tubes SA 214 Carbon Steel with Aluminum fins

- ASME Code Stamp per ASME Section VIII, Div 1 with Nat’l Board Registered included

*Contact NGSG for details